Success Story: Cultured Dairy Product Processing

When Tim Noll, a consultant specializing in cultured dairy products, wanted to trial a new piece of equipment for manufacturing a unique cultured dairy product, he turned to CDR Processing staff. He worked closely with CDR’s Mike Molitor, Innovator/Process Pilot Plant Manager, and Mellisa Houfe, Cheesemaker for the Processing and Cheese Groups.

Through a couple brain storming calls with Mike and then advice from an outside resource recommended by Mike, Tim decided to rent a skid containing the most promising type of process equipment for the job and test its performance at CDR. This wasn’t the first time Tim had utilized CDR’s Processing capabilities to successfully conduct ‘plug and play’ trials to evaluate rental equipment.

“We brought it to CDR and before we arrived, we told Mike the requirements as far as what was provided with the rental, what essential utilities were necessary and what we trusted CDR could provide regarding axillary equipment to test the machine’s capabilities.” Noll said.

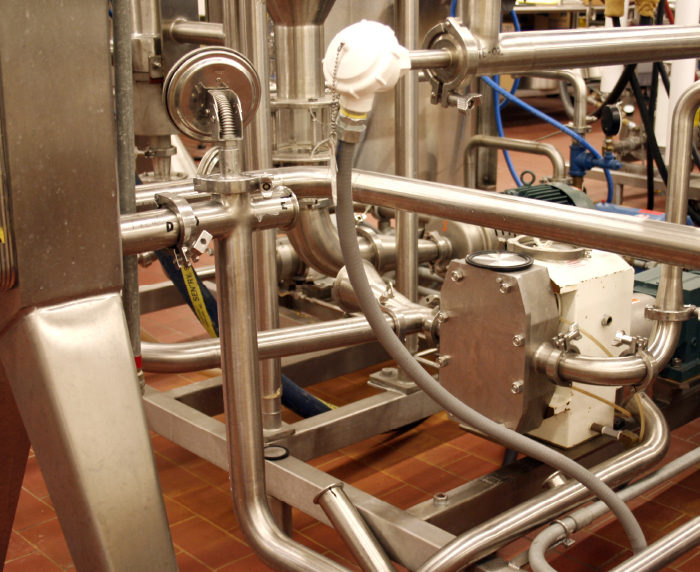

Mike and Mellisa moved it into their pilot plant and choose a location centrally located to the necessary utilities. Then they set it up for evaluation by utilizing the Processing groups range of ‘plug & play’ hardware including, a portable jacketed processor equipped with powerful vertical agitation, a portable rotary lobe positive displacement pump with variable speed drive, two magnetic flow meters, digital pressure & temperature gauges plus a variety of sanitary hoses, tubing and valves necessary for CIP and product flow options.

The next day was devoted to starting up the process, but the electronic valve that came with the rental didn’t function correctly. Mike and Mellisa worked with us for hours to trouble shoot and communicate with the vendor but eventually the day was lost, and plans were made for the manufacturer’s rep to came to Babcock Hall the next morning and resolve the issue. The rep couldn’t fix the valve either and so we proceeded to run the trial without it.

“Thus, once we got it running, the trial went really well,” Noll said.

“Tim said overall CDR gets a 'very high grade'... He emphasized the value of working in the CDR pilot plant because of the combination of knowledgeable staff, the broad range of sanitary hardware available along with the necessary utilities to accomplish ‘plug & play’ trials.”

Tim added that the flexibility of working in the CDR pilot plant and the knowledge of staff was very valuable.

“What’s nice about working with Mike and Mellisa was how quickly they could adapt to changes. For instance, we wanted to speed the motor up and slow it down and then run it in recirculation mode and it was great because they could respond to our requests within minutes. And we got valuable data from each one of those options that we ran.”

Tim said overall CDR gets a “very high grade” from himself and he emphasized the value of working in the CDR pilot plant because of the combination of knowledgeable staff, the broad range of sanitary hardware available along with the necessary utilities to accomplish ‘plug & play’ trials that offers the dairy industry a confidential setting to evaluate new equipment. That’s all so crucial to make an informed purchasing decision.

“You couldn’t hardly do that in your own plant. If you did, you’d have to devote a ton of resources to it. I just was very pleased working with CDR.”